You thought you were just dimensioning a hole. Next thing you know, you’re knee-deep in Excel, running trig functions in random cells, trying to figure out why the assembled part is 0.4 mm out of alignment and your boss is making that face again.

Welcome to tolerance stack-ups: the subtle but ruthless saboteur of otherwise good designs.

This guide is your no-fluff walkthrough of what tolerance stack-ups are, why they matter, how to actually do one, and what to do when the numbers don't work out.

What Is a Tolerance Stack-Up?

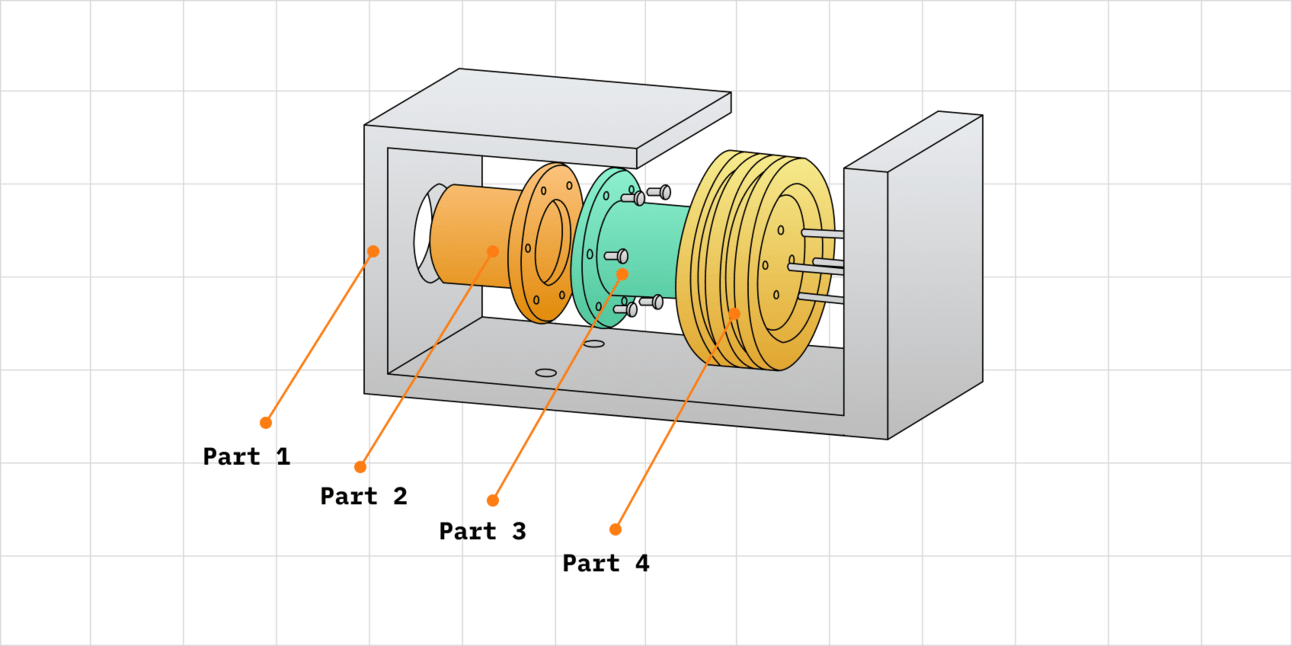

A tolerance stack-up is a method used to calculate the cumulative effect of part tolerances in an assembly. It tells you whether parts will still fit and function properly when every feature is manufactured with some deviation from its nominal value.

Every dimension on a part has a tolerance—a range within which it's allowed to vary. When multiple parts fit together, these small variations can add up in ways that cause parts to misalign, bind, or have excessive gaps.

If too many of these parts have loose tolerances than the greater assembly may not be able to fit together

When Do You Need a Stack-Up Analysis?

Any time you're designing for:

Fit: press fits, clearance fits, slip fits, snap fits

Alignment: holes across multiple parts, optical paths, sensor views

Gaps: sealing zones, visible flushness, enclosure interfaces

Motion: linkages, cams, shafts, or any mechanism with clearances

Function: preload, clamping, gear meshing, stiffness

If a part needs to align, mate, or move reliably with another, and there is dimensional variation, you probably need a stack-up.

Terminology

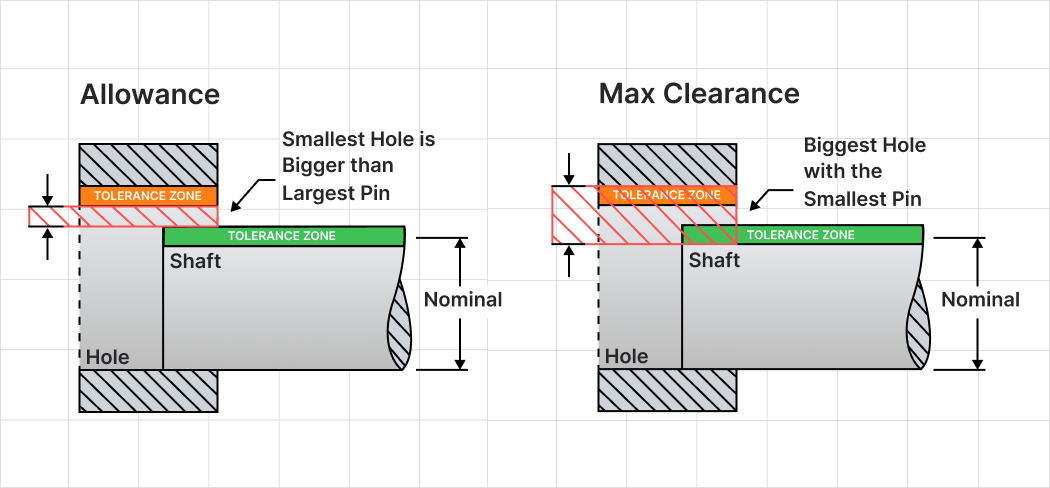

Nominal: The target dimension you specify on a drawing.

Tolerance: The allowable deviation from the nominal.

Allowance: The minimum intended clearance or interference between parts.

Worst Case Stack-Up: A method where all tolerances are considered at their limits.

RSS (Root Sum Square) Stack-Up: A statistical method assuming normal distribution.

Monte Carlo Stack-Up: A simulation-based method using randomized sampling.

Stack Path: The set of dimensions that affect the feature or gap you're analyzing.

How to Perform a Basic Stack-Up Analysis

Step 1: Define the Functional Requirement

Before you can perform a tolerance stack-up, you need to clearly define the specific functional requirement you're analyzing…

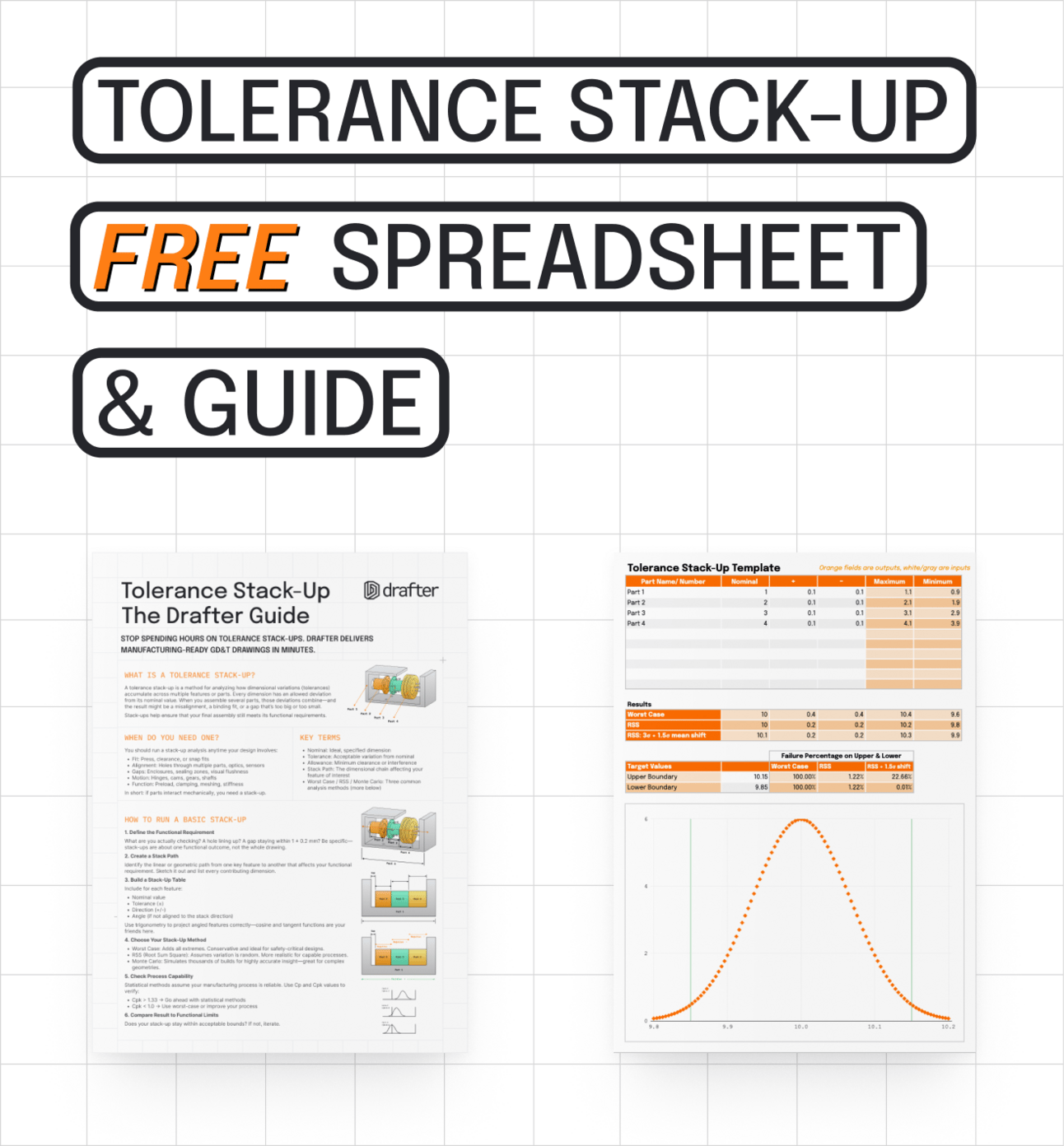

Build Better Tolerance Stack-Ups

Download our free guide and spreadsheet to save time, reduce scrap, and boost drawing accuracy.

5 minute engineering drawings with Drafter

We’re building a tool that lets you go from 3D model to manufacturing-ready 2D drawing in minutes—not hours. No more clicking through a hundred dropdowns or babysitting your title block. Just fast, clean drawings with proper GD&T, ready to send to the shop.

Whether you’re designing aerospace components or bike parts, Drafter gets you to a drawing faster than your coffee gets cold.

We’re already working with teams in aerospace, robotics, automotive, medical devices, and energy—basically anywhere engineers are tired of wasting time on the boring stuff.

We'd love your feedback! If there are specific resources or tools you'd like Drafter to create, please reach out anytime. Your input directly shapes the tools we build.

Happy engineering,

The Drafter Team