Designing plastic parts seems simple—until your molder sends back photos of flash, warp, or a half-filled cavity.

Our free 17-page DFM PDF shows you exactly how to design parts that mold right the first time. Learn how to balance wall thickness, gate placement, and cooling like a pro—without finding out the hard way on your next tool.

Preview: Introduction

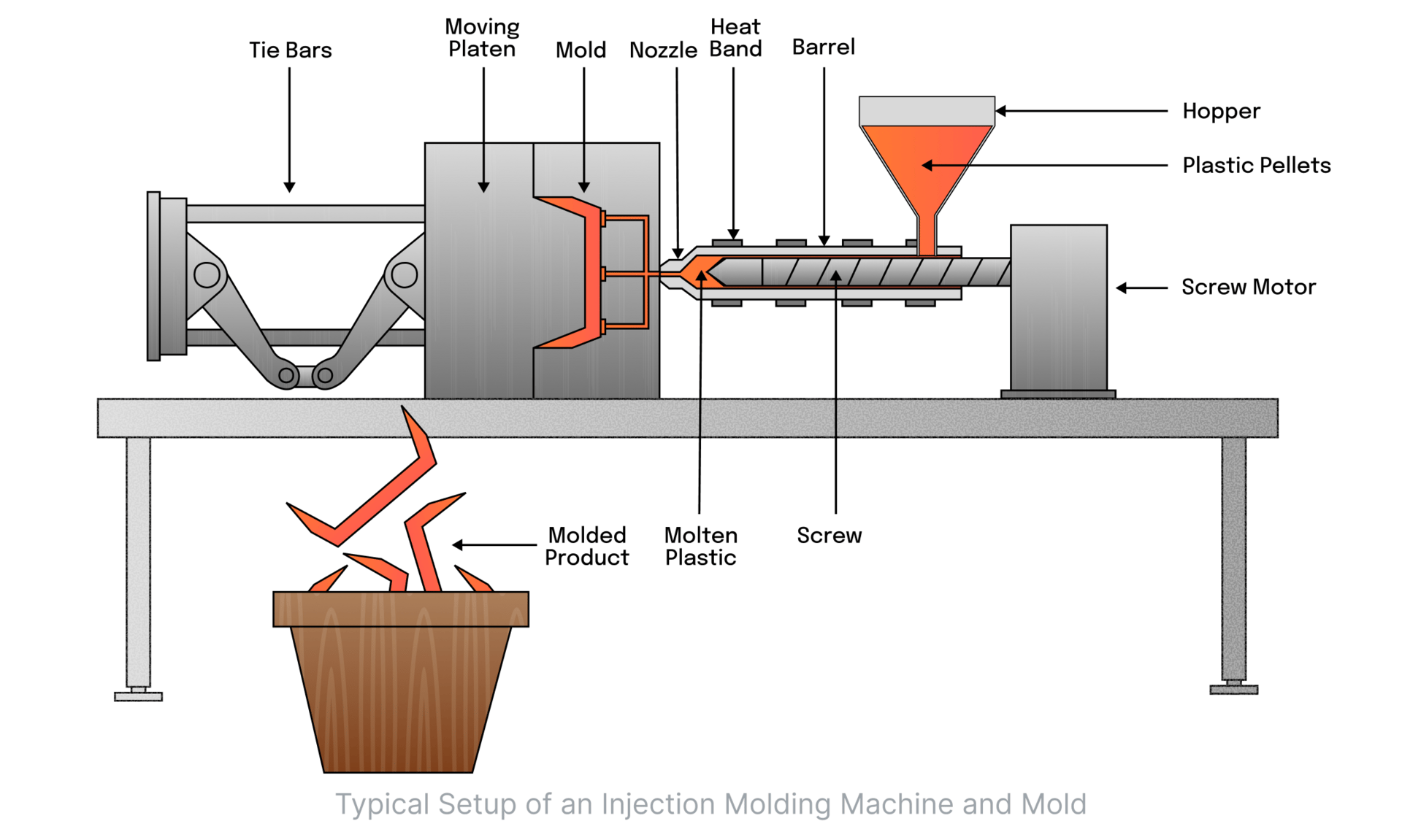

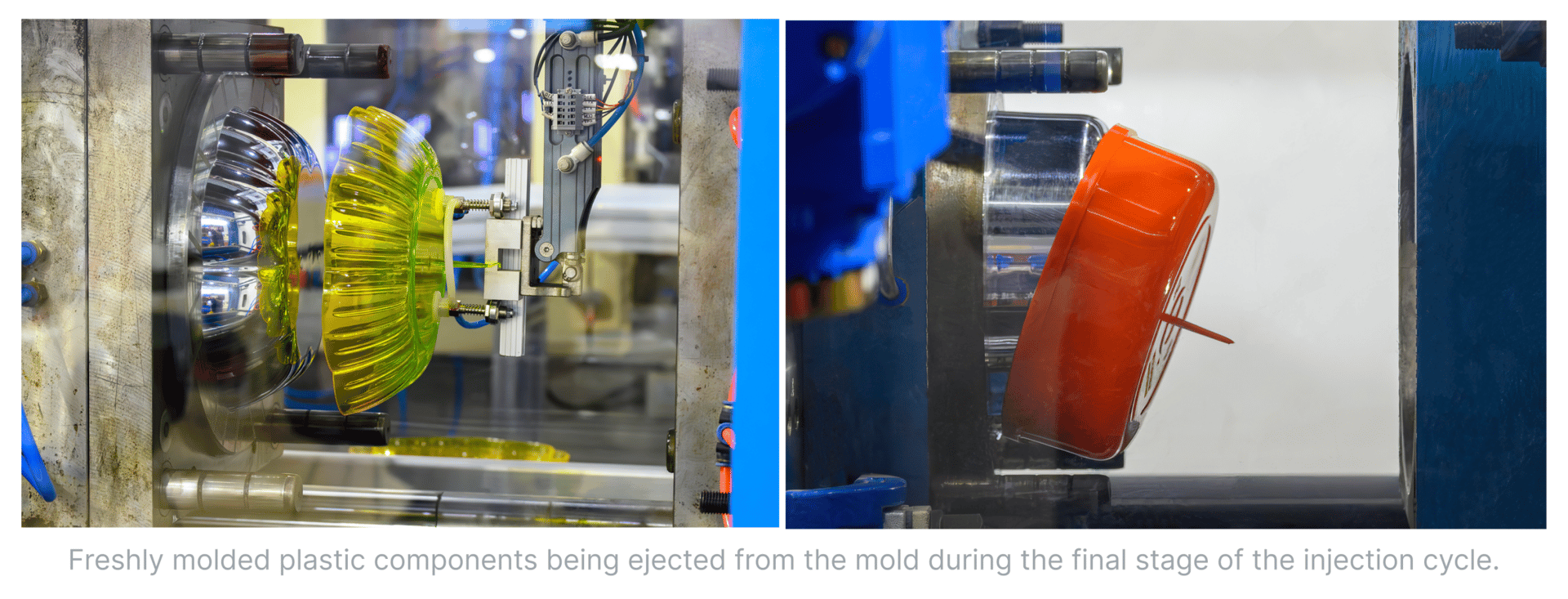

Injection molding is a fast and repeatable process used to produce plastic parts at scale. It relies on a steel or aluminum mold made of two halves—Commonly called A side (cavity) and B Side(Core) —that come together to form the part’s shape. Molten polymer is injected into the mold under high pressure, fills the cavity, and cools into a solid part. Once cooled, the halves separate and eject the part. This cycle can take anywhere from a few seconds to minutes, depending on part size, resin type, and cooling design.

Basics of Injection Molding

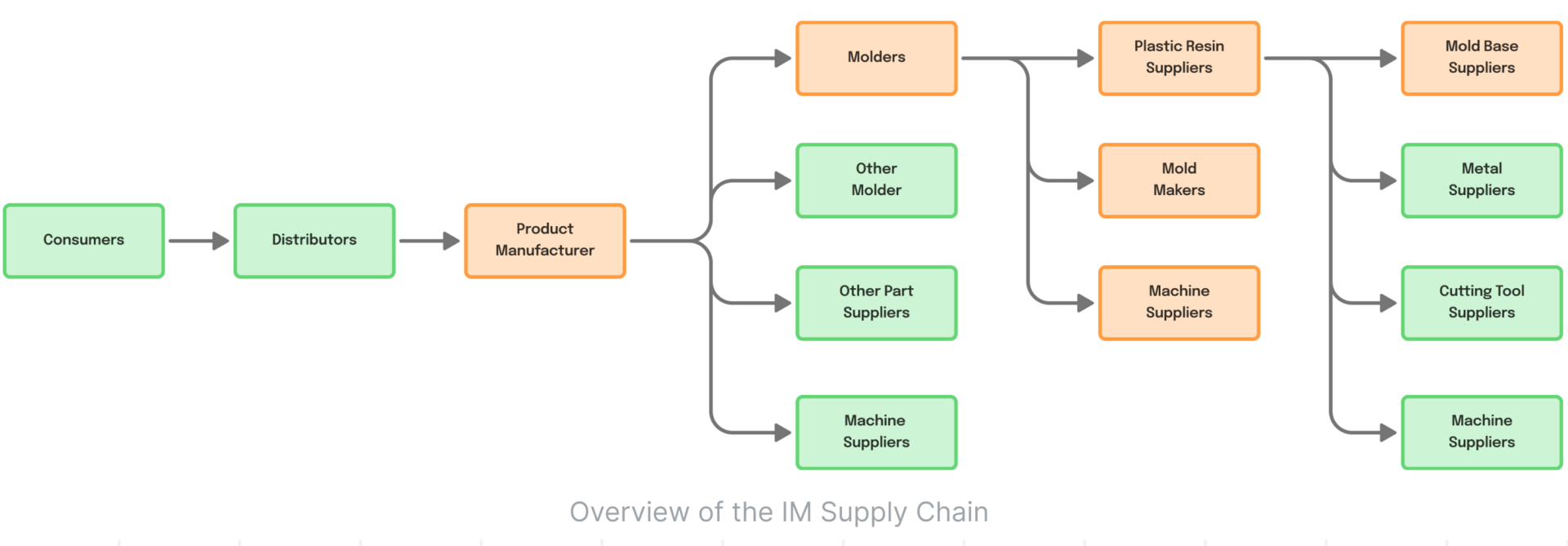

Think of injection molding as a process defined by its tool. The mold captures every contour, texture, and tolerance of the final part, and once it’s cut, those choices are fixed. When production volumes justify the upfront tooling cost, IM is incredibly efficient in use across thousands to hundreds of thousands of identical parts, each shaped by the same piece of steel.

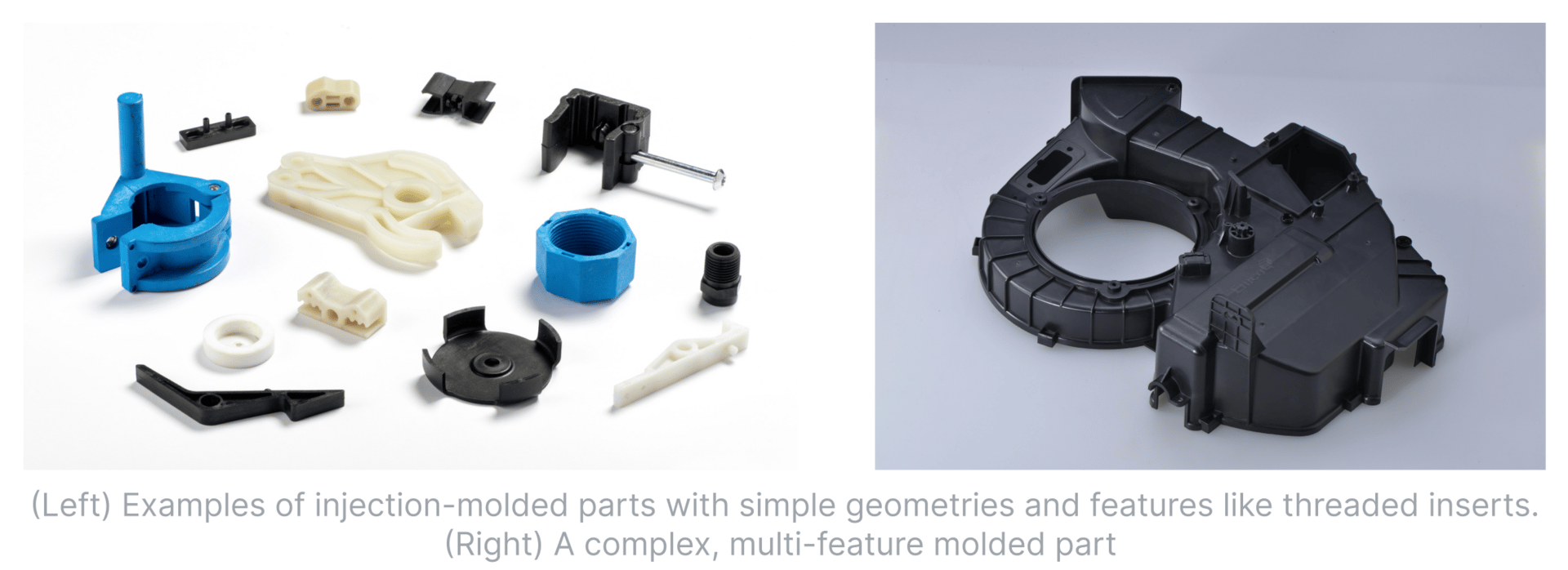

Applications: Medical parts/assemblies, Consumer electronics, automotive trim, packaging, and any geometry requiring high precision or integrated features like snaps, bosses, and living hinges.

The same process can be used to mold parts as large as an automotive bumper or as small as a connector housing or button cap. Micro-molding can be used to create parts barely seen with the naked eye.

Economics: Tooling is the major upfront cost and often the longest lead item in the schedule for hardware programs. A single-cavity production mold may range from $20k to $100k, but once built, cycle times are fast and part-to-part repeatability is unmatched. At scale, tooling amortization drives part cost down by orders of magnitude (e.g., a $50k tool producing 500k parts adds only $0.10 per part).

Design Considerations

Parts must account for molding behavior of the selected plastic. Tooling changes later are slow and costly, so mold design is critical to part performance.

Basic Process Overview & Types of Molds

An injection molding press has three main systems: the injection unit, the clamping unit, and the mold…

5 minute engineering drawings with Drafter

We’re building a tool that lets you go from 3D model to manufacturing-ready 2D drawing in minutes—not hours. No more clicking through a hundred dropdowns or babysitting your title block. Just fast, clean drawings with proper GD&T, ready to send to the shop.

Whether you’re designing aerospace components or bike parts, Drafter gets you to a drawing faster than your coffee gets cold.

We’re already working with teams in aerospace, robotics, automotive, medical devices, and energy—basically anywhere engineers are tired of wasting time on the boring stuff.

We'd love your feedback! If there are specific resources or tools you'd like Drafter to create, please reach out anytime. Your input directly shapes the tools we build.

Happy engineering,

The Drafter Team